THE COUNTER TO CHINESE HYPERSONIC NUCLEAR MISSILES: A US DRONE SUBORBITAL AIRCRAFT POWERED BY ANTI GRAVITY OR NUCLEAR PROPULSION LOADED WITH HYPERSONIC NUCLEAR MISSILES

Area 51, secret U.S. Air Force military installation located at Groom Lake in southern Nevada. It is administered by Edwards Air Force Base in southern California. The installation has been the focus of numerous conspiracies involving extraterrestrial life, though its only confirmed use is as a flight testing facility. For years there was.........

Booster rocket failure stops U.S. hypersonic weapon test

A booster rocket carrying a hypersonic glide body failed to launch Thursday morning during a test by the Defense Department's hypersonic weapons program.

"The test did not occur as planned due to a failure of the booster stack," Defense Department spokesman Lieutenant Commander Tim Gorman told CBS News in a statement about the attempted test, which took place in Alaska. Gorman stressed the failure was not related to the hypersonic technology, just the booster.

"The booster stack used in the test was not part of the hypersonic program and is not related to the Common Hypersonic Glide Body. The missile booster is used for testing purposes only."The test took place at the Pacific Spaceport Complex-Alaska in Kodiak, and was conducted to inform hypersonic technology development. Despite the setback, the department is still on track to fielding offensive hypersonic capabilities in the early 2020s, according to Gorman. A precision sounding rocket. / Credit: Courtesy of U.S. Navy

A precision sounding rocket. / Credit: Courtesy of U.S. Navy

Hypersonic weapons can travel within the upper atmosphere at five times the speed of sound.

The failed test comes after the Navy and Army successfully tested precision sounding rockets Wednesday. The rockets take measurements that aid in U.S. hypersonic development.

"During weapon system development, precision sounding rocket launches fill a critical gap between ground testing and full system flight testing," The Navy said in a statement. The statement went on to say that launches like this one would help speed the development of offensive and defensive hypersonic technology.

The U.S. tests come amid reports that China has been testing hypersonic weapons.

The Financial Times reported China conducted a test of a nuclear-capable hypersonic missile in August. The hypersonic glide vehicle flew through low orbit towards its target and only missed by about 24 miles. The Daily Mail also reported China had conducted another test in July.

On Wednesday, President Biden said he was concerned by the reported Chinese tests.

Secretary of Defense Lloyd Austin was also asked about China's alleged tests this week and declined to comment, but he told the reporters traveling with him to Tblisi, Georgia, that the U.S. keeps a close watch on the development of China's military capabilities.

"You heard me say before that China is a challenge, and we're going to remain focused on that," Austin said.

Propulsion Technologies

If the performance required of a UAV is similar to the performance of conventional aircraft, the propulsion system may also be similar. Many UAVs will weigh more than 1,000 pounds, fly at subsonic and supersonic velocities at altitudes below 60,000 feet, maneuver at 9g’s or less, and will be maintained in ways similar to current military or commercial aircraft. These UAVs will not require unique propulsion technology. Indeed, many new aircraft of all types are designed to use existing engines to avoid the time and expense of developing new engines. This chapter discusses UAV concepts that require new propulsion technology.

Some classes of UAV require new engine technology, new designs, or even new fundamental research and propulsion concepts. For example, a UCAV may require a gas turbine engine that can operate at much more than the 9g forces that limit manned vehicles. For high g loadings, the entire engine structure, especially the rotor support, will have to be reevaluated. An engine capable of maneuvering at 30g, for example, would require new design concepts that could require considerable engineering development but not new basic research. Nevertheless, for some UAVs, the propulsion system is a critical limiting technology. These include subsonic HALE aircraft that must operate above the altitude limits of current engine technologies; MAVs; and very low-cost, high-performance vehicles.

BACKGROUND

In addition to thrust, propulsion systems for modern aircraft must provide high fuel economy, low weight, small size (to limit drag), and extremely high reliability. The primary engine performance metrics are minimum total fuel burn

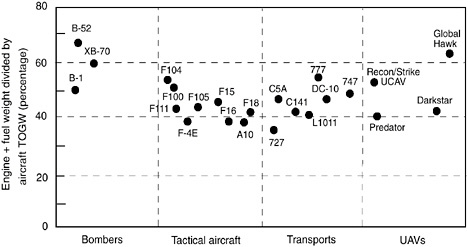

(while meeting aircraft performance requirements) and reliability levels commensurate with permissible aircraft loss rate (1 per 108 departures for commercial aircraft). Many military missions also require stealth, which greatly affects engine design and installation. For all types of aircraft (including UAVs), engines and fuel typically account for 40 percent to 60 percent of gross takeoff weight, and the performance of the propulsion system has an enormous effect on air vehicle performance (Figure 5-1).

The gas turbine engine is vastly superior to alternative engines in all propulsion metrics. This high level of performance reflects the intrinsic merits of the concept and the $50 billion to $100 billion invested in gas turbine research and development over the past 50 years. The power-to-weight ratio of gas turbines is three to six times that of aircraft piston engines. The difference in reliability is even greater. The in-flight shutdown (IFSD) rate, a measure of reliability, for gas turbine engines in large commercial aircraft is 0.5 shutdowns for every 105 hours of flight. For single-engine military jet aircraft, the IFSD rate is 2 for every 105 hours. The IFSD rate for light aircraft piston engines is considerably worse, about 5 to 10 for every 105 hours. Although the IFSD statistics are not available for small piston engines in current UAVs, anecdotally, they are even higher. Gas turbines can also operate for long periods of times (4,000 to 8,000 hours) between overhauls, compared to 1,200 to 1,700 hours for aircraft piston engines. The small piston engines in current UAVs are replaced every 100 hours or less of service. The attractiveness of small piston engines is their low cost and the lack of availability of high-performance gas turbines in very small sizes. Alternative propulsion concepts may only be desirable when suitable gas turbines are not available.

FIGURE 5-1 Propulsion system weight (engine plus fuel) as a percentage of aircraft takeoff gross weight (TOGW).

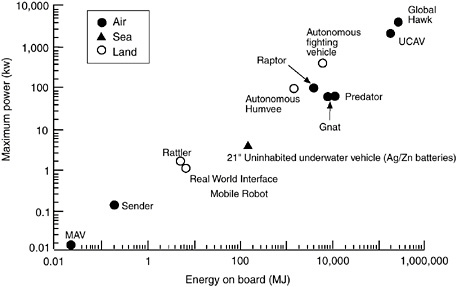

Both energy density and power density are important factors for propulsion systems. Energy density is a measure of the energy in the fuel and the conversion efficiency of the power converter (engine). Power density is a measure of the power converter. For example, the propulsion system weight of a long-range transport aircraft is dominated by the energy density of the fuel consumed (which may be 10 times the weight of the engines). In contrast, a solar-powered vehicle has zero fuel weight and, thus, very high energy density but low power density (the solar cells and power storage system are heavy). Figure 5-2 illustrates the range of power and energy densities for current UAVs.

Most air vehicles require about twice as much power for takeoff and climbing than for cruising. Therefore, the design of the propulsion system is a compromise between the weight of the engine (power-to-weight ratio) required for takeoff and the fuel weight required for cruising range (e.g., engine efficiency). The interactions between these factors for particular power system technologies will be discussed below.

Development cost has been a major factor for UAV propulsion systems in the past. The development of an all-new gas turbine engine for a tactical military aircraft can cost more than $1 billion, an inconceivable expense for the UAVs developed to date. Thus, the practice has been to adapt existing devices in a very budget-constrained, suboptimal manner, usually by sacrificing both performance and reliability. The cost of new technology, especially new concepts, will be as high for UAVs as it has been for conventional aircraft unless new ways for developing propulsion systems can be perfected.

FIGURE 5-2 Characteristics of propulsion and power systems for UAVs.

BASIC RESEARCH

The range of UAV missions and applications is restricted by the lack of an adequate propulsion system. Missions that may be desirable but require the development of propulsion technology include very high-altitude (above 65,000 feet) vehicles, long-endurance reconnaissance/surveillance/communications relay vehicles, MAVs, and very low-cost, high-performance UCAVs.

High-Altitude, Long-Endurance UAVs

Substantial efforts are under way to develop propulsion technologies for HALE surveillance and communications-relay missions. The mission objectives for HALE UAVs are to operate at as high an altitude as possible to maximize the geographic coverage of sensors and communications. High altitude can also be an important contributor to survivability because high altitude reduces the aircraft’s vulnerability to ground-to-air and air-to-air missiles. However, to be entirely safe from many widely deployed threats, operating altitudes must be above 75,000 or even 85,000 feet. These altitudes cannot be routinely reached with current propulsion technology.

At an altitude above 75,000 feet, there is very little air (the air density at 80,000 feet is only 3 percent of the density at sea level), which affects air-breathing fueled propulsion systems in two fundamental ways. First, engine weight is inherently higher. The fuel required to produce a unit of thrust per time is the same at high altitudes as it is at low altitudes, but the fuel-to-air ratio is fixed by the chemistry of combustion. As a result, the required mass flow rate of air is set by the power required.

Second, the large compression ratios required for gas turbines (additional compressor stages must be added), piston engines, and fuel cells (which require several stages of turbocharging) result in weight and drag penalties. The additional compression requirement significantly increases the weight of high-altitude propulsion systems. Because the compression process increases the temperature as well as the air pressure, the required pressure ratios result in temperatures that are too high for current technology. Thus, coolers (heat exchangers) must be added to the compression system. The weight and drag penalties of these heat exchangers are exacerbated by the very low ambient air density. High-altitude aircraft under development for NASA, which use piston engines, have more area and drag associated with heat exchangers than for the wings. The increased weight and drag of heat exchangers with altitude limit the operating altitude of these designs (Drela, 1996).

Areas for research include technology leading to low-weight, low-drag heat exchangers and low-weight, low Reynolds number, high-efficiency compression systems. These technologies will be important for both gas turbine and internal combustion engines, as well as for fuel cell systems (described below).

Propulsion approaches other than combustion engines have been proposed, notably fuel cells (Stedman, 1997) and solar power. Fuel-cell systems have the potential advantage of high energy densities but have relatively low power densities. Turbochargers and heat exchangers similar to those for piston engines would be required at high altitude. Unless fuel cells can operate on hydrogen (whose low density makes it difficult to integrate into an air vehicle), their complexity and weight quickly dominate the design. No liquid fuel systems are in routine operation today, and none has been designed for use in air vehicles. Fuel cells might be useful for very long-endurance missions for which fuel consumption is the dominant factor.

Because of the relatively low energy density of solar radiation, solar-powered aircraft must be extremely light and efficient, and they require exceptionally careful operation. Thus, they are probably only viable for niche military applications. The principal technology requirements for solar-powered aircraft are lighter, more efficient solar cell designs and compact, lightweight energy storage systems (for night operation).

Micro Air Vehicles

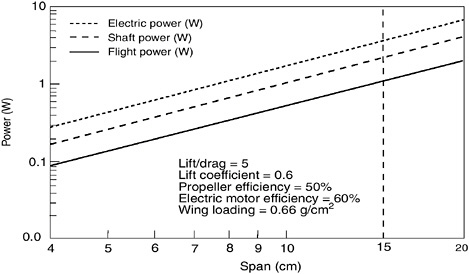

MAVs are currently defined by DARPA as having characteristic dimensions of less than 15 cm. This makes propulsion and power for MAVs very challenging indeed. A study was conducted by the Massachusetts Institute of Technology’s Lincoln Laboratory on both the propulsion requirements and the technology options available to meet these requirements (Davis et al., 1996). Figure 5-3 illustrates how the amount of power required varies as a function of vehicle size for a class of conventional airplane configurations. In the figure, the flight power curve refers to the power (thrust times flight velocity) the vehicle requires for level flight. (Climbing and maneuvering may require 50 percent to 100 percent more power than level flight.) The flight power requirement is independent of the type of propulsion system. The shaft power curve in the figure refers to the mechanical power a motor must provide with a propeller propulsion system, regardless of the type of motor (e.g., electric, internal combustion, gas turbine). Assuming that the motor is electric, the electric power curve then represents the power that must be supplied by the source of electricity. Thus, vehicles of this type need on the order of 3 to 5 watts for cruising and 6 to 10 watts for climbing.

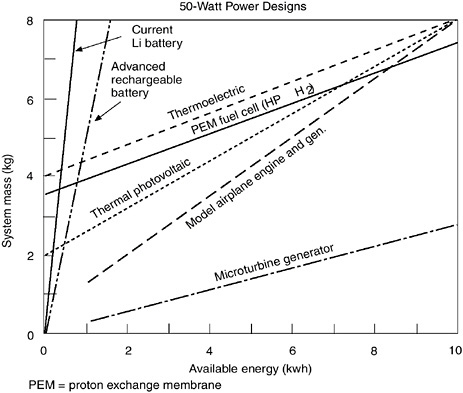

Conceptually, different propulsion systems have different relationships between motor weight and fuel weight, so the relative, overall mass of the propulsion system is a function of flight duration requirements. Figure 5-4 shows the trade-offs at the 50-watt level that would be required for some of the less power-efficient UAV concepts (e.g., hovering vehicles) (NRC, 1997b). Table 5-1 illustrates the propulsion system mass (including fuel where appropriate) to propel a vehicle with a takeoff weight of 50 grams for various flight times with different power systems (the only option that has been demonstrated is electrically driven

FIGURE 5-3 Typical power requirements for propeller-powered MAVs. Source: Massachusetts Institute of Technology, Lincoln Laboratory.

propellers). The nominal weight allowance for propulsion in the design is 36 grams; thus weights of more than 36 grams do not meet the specified flight times. The most attractive (lowest total weight) propulsion systems are airbreathing systems. The current DARPA MAV program is investigating four propulsion options: batteries, microdiesels, fuel cells, and micro gas turbines. The last three are projected to have about the same fuel consumption per unit power, but the micro gas turbine is considerably smaller and lighter.

Low-Cost, High-Performance UAVs

Reliable aircraft propulsion systems are expensive to develop, manufacture, and operate. Typical list prices range from $130 to $200 per pound of thrust for civilian engines and $200 to $400 per pound for military engines (civilian engine prices generally include amortization of the development costs; military engine prices do not). The price per pound increases as size is reduced because of relatively higher development costs and engine accessory costs (e.g., fuel pumps, controls, and electrical generators). Even “low-cost,” short-lived (10-hour) cruise missile engines cost about $150 per pound. With current technology, an engine designer can trade off lower cost for lower performance by selecting less expensive materials and manufacturing approaches and reducing the number of parts. The most important question for many UAVs will be how to realize high performance while dramatically reducing costs, especially in the smaller engine sizes.

FIGURE 5-4 System mass vs. energy for several advanced, small energy systems. Source: Massachusetts Institute of Technology, Lincoln Laboratory.

Significant cost reduction over the lowest cost with current technology will require advances in fluid mechanics, heat transfer, and materials technologies that emphasize cost instead of performance, which is traditionally emphasized. For example, increases in airfoil and end-wall boundary-layer loading can reduce the number of compressor and turbine stages, as well as the number of airfoils per stage. These increases might be realized through progress in passive (e.g., suction or casing treatment) or active (e.g., involving feedback) boundary-layer control.

Another example would be reducing the cost of hot sections (combustors and turbines) through the development of low-cost, high-temperature materials and coatings. An alternative approach would be to develop new cooling schemes that would reduce the cost of producing air-cooled parts. (A typical small engine may require drilling more than 100,000 cooling holes). Also, cooling is often less efficient in small engines because of limitations in manufacturing technology. Many fundamental problems with using vapor and liquid cooling approaches in engine environments will require basic research to be resolved.

TABLE 5-1 Total Propulsion System Mass for 50-Gram MAV

| Mass for 30-minute flight (in grams) | Mass for 60-minute flight (in grams) |

Rocket (hydrogen-oxygen) | 83 | 140 |

Pulse jet | 45 | 80 |

Electric motor (0.38 W/gram, 60% efficient) | ||

Batteries | 55 | 79 |

Solara | 35a | 35a |

Thermal photovoltaicb | 25b | 26b |

Microturbine generator | 20 | 24 |

Advanced fuel cell | 25 | 31 |

Microfan jet | 8 | 12 |

Internal combustion engine (5% efficient) | ||

Otto cycle | 13 | 22 |

Diesel cycle | 9 | 13 |

Note: Propulsion system design mass is 36 grams aSolar panel size may exceed the available surface area. bExcludes cooling drag. | ||

Another major issue for engines of all sizes, but increasingly important as engine size is reduced, is leakage flows through the clearances between stationary and rotating parts. These leakages have a first-order impact on engine efficiency and operability. Engine complexity and costs are increased significantly by design features to reduce leakage. New technology and approaches for airfoils, end-wall flows, seals, and thermostructural interaction could reduce the impact of leakage. One example that has been tried is shape-memory alloys to control compressor blade clearances (Schetky et al., 1998).

Gas bearings are feasible in small sizes and are used in small turbomachinery, such as APUs. If gas bearings were used in small aircraft engines, they could reduce the complexity and cost of the bearing and lubrication systems.

Currently, most military engines are designed for specific applications; thus development costs for each new aircraft are substantial. One radical approach to reducing these costs would be to develop a miniature, high-performance, low-cost engine that could be grouped to provide greater thrust. This “one-size-fitsall” approach, however, is well beyond the state of the art and would require basic research. Existing technology can produce only miniature, low-performance, high-cost (per unit thrust) engines. In addition to the advances discussed above, the technologies for this new approach would include very small, low-cost accessories. MEMS could be an important element in miniature engines.

UNIQUE OR ENABLING APPLIED RESEARCH

Low-Cost, Storable, Limited-Life Propulsion Systems

As currently envisioned, propulsion systems for UAVs can be divided into two broad categories: (1) vehicles operated routinely in peacetime (e.g., highaltitude reconnaissance UAVs), and (2) vehicles used only in wartime, for which most, or even all, training will be done by simulation. Engines for the first category of UAVs will have conventional operations and maintenance requirements. But the requirements of store-in-peace/use-in-war vehicles will be closer to those of cruise missiles. These vehicles will require engineering solutions for subsystems, such as fuel and lubrication systems, that must be capable of unattended storage for years and very fast start-up.

Traditionally, much of the profit for manufacturers of gas turbines has come from the sale of spare parts to replace parts consumed during military training. If vehicles are used only in wartime, manufacturers will have little or no opportunity to sell spare parts in peacetime (and thus no industry geared up to produce them), necessitating a different pricing structure for these engines. Therefore, although overall engine-related program costs might be reduced, costs would be shifted from the operations and maintenance budget to the procurement budget (i.e., the purchase price of engines would increase).

Engines are now nominally optimized for minimum life-cycle costs under the current market structure. A different life cycle can have different optimal conditions. For a given thrust, the optimum design for a 500-cycle engine life in a UCAV will be different than for a 4,000-cycle life (typical for a modern fighter) or for a 20,000-cycle life (for commercial aircraft). These differences will be apparent, for example, in the lower requirements for material creep life, maintenance, and survivability. The lower requirements might also be reflected in the selection of materials (for lower cost and weight), lighter weight structures (especially rotating parts), and less emphasis on aging and maintainability characteristics (e.g., thinner airfoils, more welds, and fewer bolted joints).

Technology for storable engines already exists for cruise missiles and smaller engine sizes (700-lb. thrust and below) with very limited lives (tens of hours). However, this technology has not been used for larger engines (more than 1,000-lb. thrust) with longer lives (500 hours), which are contemplated for UCAVs.

Propulsion for High-Speed, Highly-Maneuverable UAVs

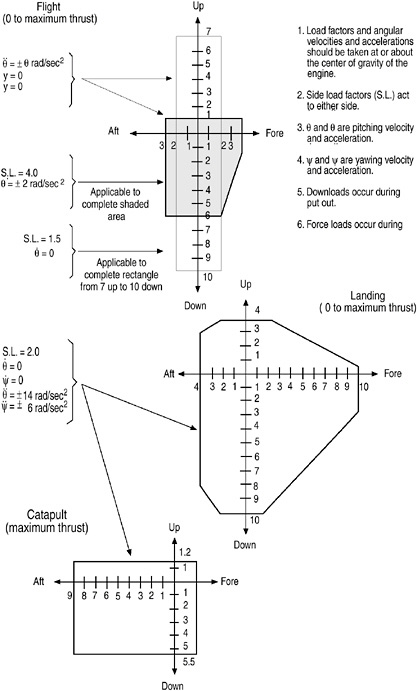

Current engine designs accommodate steady inertial loads compatible with human life (nominally up to 9g’s), as well as a capability to withstand additional impulsive loads from hard landings. (A typical military design requirement is illustrated in Figure 5-5.) If the maneuver envelope is increased for UCAVs, new

designs would have to be developed to accommodate the significantly increased g-loads. Without design changes and/or technological innovations, the higher load requirements would translate into higher weights. Steady-state, inverted flight, for example, would require the development of new bearing lubrication schemes. Even without preliminary design and system studies, it is clear that stiff, lightweight structures; better fluid-sealing; and high-load, low-life bearings will be required.

SUMMARY OF RESEARCH NEEDS

Most research on propulsion systems will benefit UAV applications. However, focused research will be needed to develop some types of UAVs. The research topics are summarized in Table 5-2.

TABLE 5-2 UAV Propulsion Technologies

| Type of UAV | ||

| HALE | HSM | Very Low-Cost |

General Topics | |||

High-altitude propulsion | E |

|

|

VTOL propulsion |

|

| E |

Modeling | I | I | I |

Cost reduction |

| I | I |

Specific Topics | |||

Low Reynolds number turbomachinery | E |

| E |

Low Reynolds number heat rejection |

|

| E |

Turbomachinery tip-clearance tolerance | I | E | E |

Leakage desensitization |

| I | I |

Thrust vectoring |

| I | I |

Magnetic bearings | I | I |

|

Air bearings |

| I | I |

Solid lubricated bearings |

| I | I |

Low-cost accessories |

| E | I |

Low-cost vapor and liquid cooling schemes |

| I |

|

Affordable high-temperature materials | I | I | I |

Cooling for small engines |

| I | E |

I = important E = enabling | |||

Recommendation. The U.S. Air Force should include research on propulsion systems for UAV applications in its long-term research program. The following general research topics should be included:

high-altitude propulsion technologies, which may include gas turbines, internal combustion engines, solar-powered motors, or fuel cells

propulsion systems for small, highly maneuverable vehicles, including vertical takeoff and landing (VTOL) capabilities

computational modeling capability to reduce the need for engine testing during development

cost-reducing technologies that, for example, reduce parts count and complexity

The following specific research topics should be considered:

low Reynolds number turbomachinery, which is very important for both high-altitude operation and very small vehicles

low Reynolds number heat rejection for high-altitude coolers and for cooling very small propulsion systems at lower altitudes

turbomachinery tip-clearance desensitization (for highly loaded engines, high-altitude operation, and very small systems)

desensitization to leakage and better, cheaper seals to reduce cost and enhance performance for highly maneuverable and very small vehicles

thrust vectoring for highly maneuverable vehicles

magnetic, air, and solid lubricated bearings to improve long-term storage, enhance high-altitude operation, and reduce complexity and cost

technologies for low-cost accessories, which tend to dominate the cost of smaller engines

low-cost vapor and liquid cooling schemes and affordable high-temperature materials (e.g., structural, magnetic, and electronic materials)

more effective cooling technologies for small engines

U.S. Air Force (USAF) planners have envisioned that uninhabited air vehicles (UAVs), working in concert with inhabited vehicles, will become an integral part of the future force structure. Current plans are based on the premise that UAVs have the potential to augment, or even replace, inhabited aircraft in a variety of missions. However, UAV technologies must be better understood before they will be accepted as an alternative to inhabited aircraft on the battlefield. The U.S. Air Force Office of Scientific Research (AFOSR) requested that the National Research Council, through the National Materials Advisory Board and the Aeronautics and Space Engineering Board, identify long-term research opportunities for supporting the development of technologies for UAVs. The objectives of the study were to identify technological developments that would improve the performance and reliability of "generation-after-next" UAVs at lower cost and to recommend areas of fundamental research in materials, structures, and aeronautical technologies. The study focused on innovations in technology that would "leapfrog" current technology development and would be ready for scaling-up in the post-2010 time frame (i.e., ready for use on aircraft by 2025).

No comments:

Post a Comment